Introduction

The skateboard deck is more than just a piece of wood; it’s the heart of the ride. It’s the platform for every kickflip, grind, and drop-in. While skaters focus on mastering tricks, engineers and designers have been working behind the scenes, constantly pushing the limits of skateboard deck technology. These advancements have transformed the simple planks of the past into highly engineered tools built for performance, durability, and style.

This article will explore the fascinating world of modern skateboard construction. We’ll break down the anatomy of a deck, look at the materials that changed the game, and discover the innovative techniques that create today’s high-performance boards. Whether you’re a seasoned skater or new to the park, understanding the tech under your feet can help you choose the perfect ride.

Understanding Skateboard Decks

Before diving into advanced technology, it’s important to understand the basic anatomy of a skateboard deck. Each feature is designed to influence how the board feels and performs.

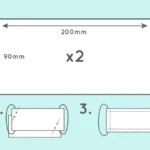

- Ply Layers: Most standard decks are made from 7-ply North American Maple. These thin layers of wood are laminated together with strong glue, creating a board that is both stiff and flexible. The number and type of plies are central to a deck’s strength and pop.

- Concave: This is the gentle curve of the deck from edge to edge. Concave helps lock your feet in place, giving you better control for flips and turns. Decks come in various degrees of concave—mellow, medium, and steep—to suit different riding styles.

- Kicktail and Nose: These are the upward curves at the ends of the board. The tail (usually steeper) and nose (often mellower) provide the leverage needed to pop the board into the air for ollies and other tricks. The shape and angle of these kicks significantly impact skateboard performance innovations.

Materials That Changed the Game

While maple wood remains the industry standard, the search for lighter, stronger, and more responsive decks has led to the adoption of advanced skateboard materials.

The Reign of Maple

For decades, North American Maple (also known as Hard Rock Maple) has been the go-to material. Its dense grain provides the perfect combination of rigidity for stability and flexibility for pop. The 7-ply construction became the gold standard because it offered a reliable and consistent feel that skaters could depend on.

The Rise of Composites

The real revolution in skateboard deck technology came with the introduction of composite materials. Manufacturers began experimenting by adding non-wood layers to enhance maple’s natural properties.

- Fiberglass: Adding thin layers of fiberglass to the deck’s construction adds significant strength without much extra weight. It creates a stiffer board with a longer-lasting pop, as the fiberglass helps the wood maintain its shape and resist fatigue over time.

- Carbon Fiber: This is a premium option for creating some of the most durable skateboard decks available. Carbon fiber is incredibly light and strong. Decks with carbon fiber layers or discs inserted near the trucks are highly resistant to impact, reducing the chance of breaks and extending the deck’s life. These decks often have a crisp, powerful pop that many skaters love.

- Bamboo: As an eco-friendly alternative, bamboo has gained popularity. It is lighter and more flexible than maple, offering a unique feel that is great for cruising and carving. While often not as durable for high-impact street skating on its own, bamboo is frequently used in composite decks to add flex and reduce weight.

Innovative Construction Techniques

How a deck is made is just as important as what it’s made of. Modern skateboard construction techniques have refined the process to create boards that are more consistent, durable, and visually appealing.

Pressing and Gluing

The method used to press the wood plies together has a massive impact on the final product.

- Cold-Pressing: Many high-end brands use cold-pressing techniques. This process involves pressing the plies in a mold for an extended period without added heat. It allows the glue to cure more naturally, resulting in a stronger, longer-lasting bond and a more consistent concave.

- Individual Pressing: Instead of pressing multiple decks at once, some manufacturers press each deck individually. This ensures that every board gets the same pressure and shape, eliminating the inconsistencies that can occur in a multi-deck press.

Impact-Resistant Technologies

To combat the wear and tear of modern skating, companies have developed specific features to make their decks tougher. Some boards feature impact-resistant inserts or reinforced layers, often made from carbon fiber or tough plastics. These are strategically placed in high-stress areas, like around the truck mounts, to prevent pressure cracks and outright snaps.

Advanced Graphics Application

Deck graphics are a huge part of skate culture, and technology has improved this aspect as well. Heat transfer graphics are now the industry standard. This process uses heat and pressure to apply the graphic directly to the bottom ply of the deck, creating a durable and vibrant image that is more resistant to scratches and wear than older screen-printing methods.

Performance Benefits for Skaters

So, what do all these advancements mean for the person actually riding the board? The evolution of skateboard deck technology translates directly into tangible performance benefits.

- Enhanced Pop: Lighter and stiffer materials like carbon fiber create a quicker and more powerful “snap” when a skater pops the tail. This means higher ollies and more responsive flip tricks.

- Improved Durability: Advanced materials and construction create durable skateboard decks that can withstand the high impact of street and park skating. This means fewer broken boards and a deck that maintains its pop and shape for longer.

- Reduced Weight: Lighter decks are easier to flip and maneuver. By incorporating materials like bamboo and carbon fiber, manufacturers can shed weight without sacrificing strength, making technical tricks feel less strenuous.

- Consistent Feel: Modern construction techniques ensure that each deck from a specific mold feels nearly identical. This consistency allows skaters to adapt to a new board quickly without having to adjust their technique.

The Future of Skateboard Deck Technology

The innovation isn’t stopping—the future promises even more exciting developments.

We are likely to see a greater focus on eco-friendly materials and production methods. Companies are already exploring recycled materials and more sustainable wood sources. The use of plant-based resins and other green alternatives to traditional glue is also on the horizon.

Another area of exploration is “smart decks.” Imagine a skateboard with embedded sensors that could track your speed, trick count, or the height of your ollies, sending the data to an app on your phone.

Conclusion

Ultimately, the drive for better performance will continue to push the boundaries of what’s possible. From new composite materials to radical new shapes, skateboard deck technology will keep evolving, helping skaters push their own limits and redefine the sport for generations to come.